On August 6, local time, the White House Oval Office put on an elaborate “Win-win show.”.

Trump has announced a high-profile 100 per cent tariff on imported chips and semiconductors, but has shown leniency to companies setting up factories in the US for nothing.

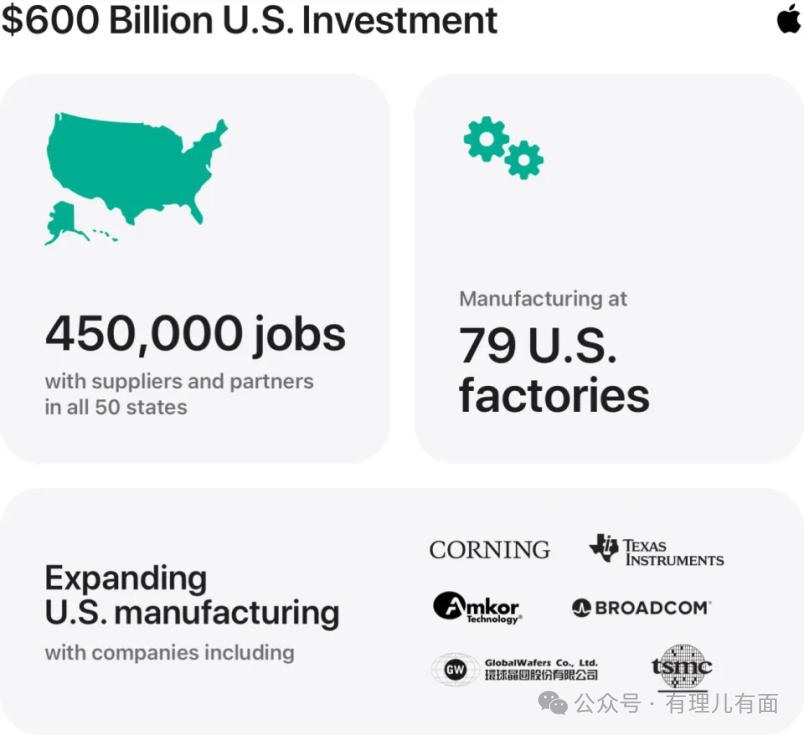

That same day, Apple CEO Cook took the opportunity to pledge an additional $100 billion in investment, bringing Apple’s total investment in the United States to a staggering $600 billion. He also presented a special gift: A glass disc set in 24-karat gold.

The gift, Corning Inc. by iPhone glass suppliers, features the apple logo, Donald Trump’s name and the words “Made in the USA” and “From Utah”.

Who says America isn’t sophisticated? This flattery! The golden return hit Donald Trump right in the heart.

However, the Netizen sees through at one stroke, will apple this behavior, calls the tribute to exchange for the death-free gold medal. This naked exchange of interests not only opened the curtain on the most expensive political transaction in the history of technology, but also tore open the absurd veil of“Made in America”.

The gilded base is encased in fragile glass, like Donald Trump’s invulnerable “Made in America”– shiny but vulnerable.

Why do you say that?

First, the irony of Cook’s carefully crafted gift from birth to delivery.

Presented as a gift of “American heritage,” the 24-carat gold base is labeled “From Utah,” but in fact the United States produces only 4 percent of the world’s gold; glass is made in Khang Ninh; But in fact the core rare earth raw materials more than 90% dependent on imports.

In other words, so-called“Home-made”, but a collage of global supply chain.

Cook went out of his way to stress that the gifts were designed by The Marine, in an apparent attempt to curry favour with Donald Trump by exploiting “Military-industrial spirit” and “Patriotism”. But the show exposed Apple’s anxieties about the need for policy cover in return for business security.

More to the point, Donald Trump’s promises were always changing — “Only tomorrow’s Donald Trump can defeat today’s Donald Trump.”. Isn’t the fragile promise between businessmen and politicians, like the shattering physics of glass, emblematic of the fragile nature of the“Made in America comeback”?

When the reporter was asked if he would assemble the entire iPhone in the United States, “Many components such as semiconductors, glass and facial recognition modules are already made in the US, but final assembly will remain overseas ‘for some time’ ,” Cook admits

In the end, the gift was apple’s“Capitulation”-the localisation of glass and chips in exchange for tariff exemptions, the“Backflow of glass panels” gimmick to coax politicians, but quietly saved the lifeblood of the global industrial chain.

In fact, this is the status quo of many American companies to survive, with Trump’s flattery in exchange for living space.

The vulnerability of glass to shatter at the touch exposes the fragile nature of the made in America program. It can not afford to be buffeted by markets, costs and the realities of the global industrial chain.

And how much of Apple’s promised $600 billion pie can fall on?

Apple’s alleged four-year, $600bn “American manufacturing programme”-LRB-AMP) looks ambitious, but it is also black comedy.

Apple said it would invest $2.5 bn in Conning to build “The world’s largest and most advanced smartphone glass line” in Kentucky, ensuring 100 per cent american-made glass covers.

But the fact is, glass raw materials such as rare earths, high-purity silicon still rely on a lot of imports, it can still be called 100% made in the United States?

Even in the United States local plant, but also need to import lithography machine, such as“Neck” technology. Apple’s so-called“End-to-end semiconductor supply chain”, 100% made in the US, looks magnificent, but the delays in building TSMC’s Arizona plant and the frequency of yield problems have proved that rebuilding a broken chain is not something that can be done overnight, nor can it be done by a single company or a single country.

On top of that, Apple claims to be adding 20,000 jobs, but 90 per cent is focused on software development, with partners such as Conning providing most of the manufacturing jobs. In Khang Ninh, where 80% of factories are automated, fewer than 800 new jobs have been created.

Clearly, what apple is promising is just a numbers game.

Besides, history has told us the answer. Back in the Donald Trump 1.0 era, Apple painted a similar pie.

At the time, Donald Trump had declared that “Apple will bring the iPhone back to US production”, but only a handful of high-end models or experimental projects were eventually launched, with the vast majority of iphones still being produced at Asian factories such as Foxconn.

Today, the $600BN investment is a replay of the script.

Moreover, will anyone really pay for the“Made in America premium”?

The cost of labour, land and energy in the US is much higher than in Asia. Even if some of Apple’s components are localised, the cost of an iPhone could jump more than 30 per cent if it is assembled in the US, according to industry analysis.

If it were 100% made in the U.S. , Apple would cost $3,500. How many consumers could afford it, not to mention how many would pay for it?

So Apple’s $600BN investment is essentially a strategic concession to Donald Trump’s policies, not a real revolution in Apple’s supply chain foundations.

Obviously, in order to survive, the apple can not come back.

So Can American manufacturing come back as Donald Trump would like? That is also a big question mark.

Apple’s “Glass-hearted dilemma” epitomises Donald Trump’s whole “Made in America”. The President held up the banner of“Bringing manufacturing back”, brandishing a tariff stick with little effect.

Under Donald Trump 1.0, he declared that he wanted to “Create millions of manufacturing jobs” and let companies like ford and Foxconn “Build factories in America”. But what happened?

US manufacturing employment growth from 2018 to 2020 was weak and far below pre-financial crisis levels, while Foxconn’s“LCD panel factory” in Wisconsin was reduced to a“Research and development centre” and employment commitments were slashed, the data showed.

More ironically, Donald Trump’s so-called high tariffs, which appear to protect local industries, actually push up costs for American businesses and hurt local consumers. The Yale Lab calculates that continued high tariffs will add $2,400 a year to average household spending and slow GDP growth.

The 100 per cent tariff, if implemented, may stimulate domestic chip factories in the short term, but in the long term it will only lead to soaring prices for consumer electronics and technology equipment, dragging down US technology competitiveness.

What’s more, manufacturing is no longer a closed-door operation, but a global division of labor. Even if the United States spends a lot of money to rebuild part of the capacity, it is difficult to get away from China’s rare earths, Japan and South Korea Precision Materials, advanced equipment in Europe and other key links.

So the essence of Donald Trump’s “America first” is an attempt to counter economic laws with political fiat. The result is bound to be a “Fragile heart”, with policies that look hard and gilded and reality riddled with a tap.

Gold-plated and fragile, who is Donald Trump’s fool to make a return to the dream?

Apple was giving Donald Trump the benefit of the doubt, and Donald Trump was giving America the benefit of the doubt.

Donald Trump needs a made-in-america victory to burnish his record and bolster his vote, while Apple needs a policy exemption to maintain profits. The Investment Show-and-gift Act at the White House was essentially a political deal in which each side got what it needed.

But consumers, workers and the chain are paying the price. Apple’s phones cost more because they were made in the United States, and it is the American blue-collar industry that will be disappointed if the industry is slow to rebuild and jobs are promised.

Foxconn’s Wisconsin plant has long been a“Mosquito House”, TSMC’s Arizona plant is mired in a delay scandal, and apple’s“Glass Americanisation” is just a side revolution in the supply chain.

Apple has pledged $600bn to buy policy insurance and Donald Trump has endorsed a gold-plated track record. But the physics of glass have long predicted the end. Donald Trump’s dream of a return to manufacturing looks like a dream.

Images from the network